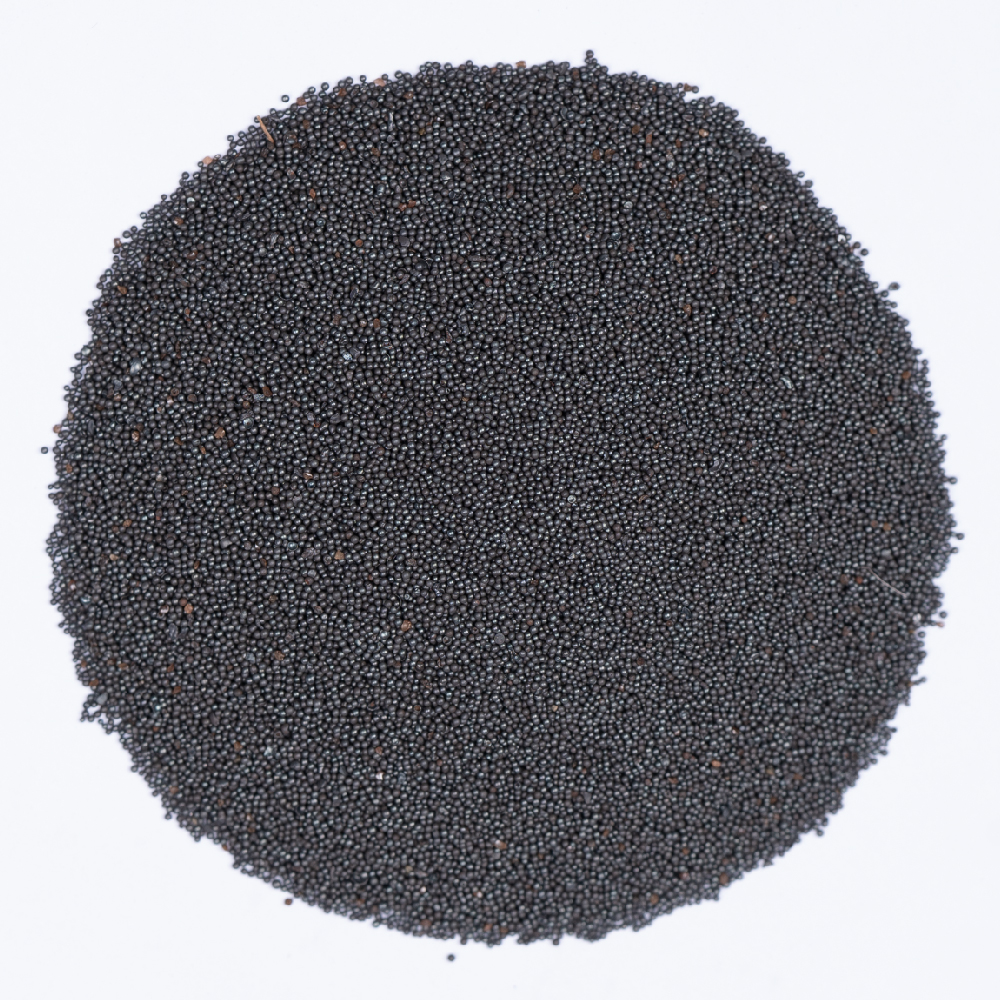

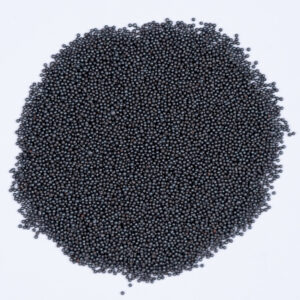

Steel Shots S-110

Steel shots with a size designation of S-110 refer to a specific grade and particle size within the abrasive blasting industry. The “S” stands for steel, indicating the material composition, while the number “110” denotes the sieve mesh size. In this context, S-110 steel shots have a particle size distribution that corresponds to the 110 mesh size, indicating a finer and more uniform grain structure. This particular size is often utilized for applications where a smoother surface finish is desired, such as in industries like automotive manufacturing or aerospace. The S-110 steel shots are known for their efficiency in removing rust, scale, and other contaminants from surfaces, making them a popular choice for shot blasting operations aiming for precision and quality surface preparation. The controlled size and hardness of S-110 steel shots contribute to their effectiveness in achieving consistent results while minimizing abrasive wear and prolonging equipment life.

Reviews

There are no reviews yet.