Introduction

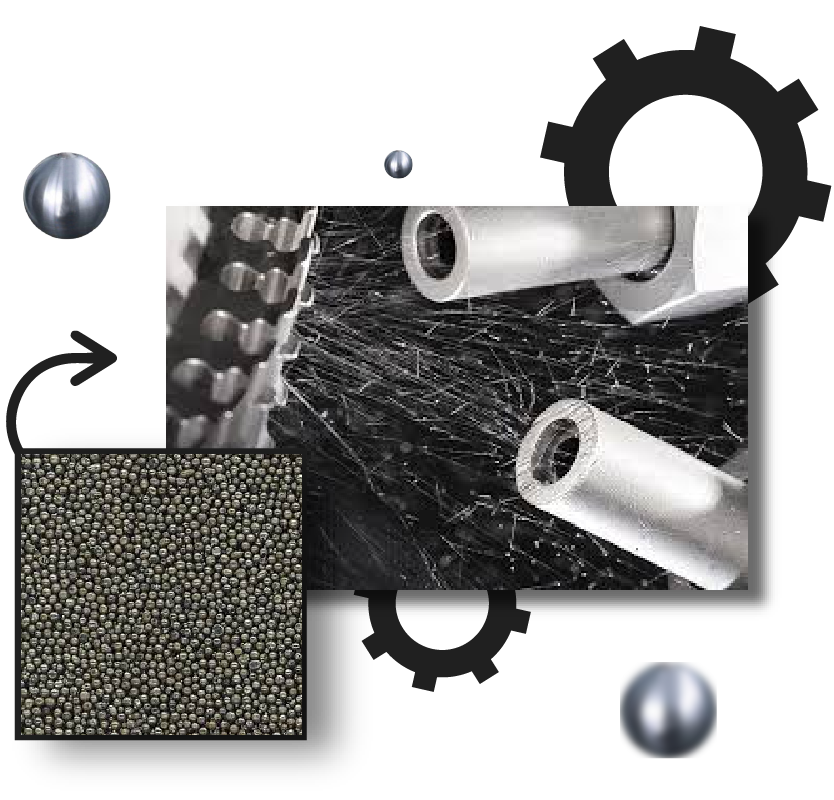

Abrasive blasting is a widely used technique for surface preparation and cleaning in various industries, such as manufacturing, construction, and automotive. It involves propelling abrasive media onto a surface at high velocity to remove contaminants, rust, old coatings, and other unwanted substances. Among the different types of abrasives available, steel shot has gained popularity for its numerous advantages and superior performance. In this article, we will explore the advantages of steel shot in abrasive blasting and why it is a preferred choice for many professionals.

1. High Durability and Reusability

One of the significant advantages of steel shot is its exceptional durability and reusability. Steel shot is made from high-quality steel, which undergoes a specialized heat treatment process to achieve the desired hardness and resilience. This treatment results in a durable abrasive that can withstand multiple impacts without breaking down. Unlike other abrasives that tend to fracture or shatter during the blasting process, steel shot maintains its integrity and continues to provide effective results. Additionally, its reusability allows for cost savings and minimizes waste generation, making it an environmentally friendly option.

2. Consistent Shape and Size

Steel shot is manufactured to have a consistent shape and size, which contributes to its superior blasting performance. The shot is typically spherical or slightly angular, ensuring uniformity during the blasting process. This uniform shape facilitates even and efficient coverage of the surface being blasted, leading to consistent results and improved productivity. The precise sizing of steel shot also allows for better control over the blasting parameters, such as velocity and flow rate, ensuring optimal performance and reducing the risk of damage to the substrate.

3. High Cleaning and Surface Preparation Efficiency

Steel shot offers excellent cleaning and surface preparation efficiency due to its high impact energy and effective removal capabilities. When propelled onto a surface, the steel shot’s kinetic energy helps dislodge contaminants, scale, rust, and old coatings, leaving behind a clean and properly prepared surface. The combination of its durability and consistent shape enables steel shot to maintain its cutting ability throughout the blasting process, resulting in efficient and thorough surface cleaning. This efficiency is especially crucial in applications where a pristine surface is required for subsequent coatings or treatments.

4. Reduced Dust and Contamination

Compared to some other abrasive media, steel shot generates significantly less dust during the blasting process. The reduced dust levels make the work environment safer and more comfortable for operators, reducing the risk of respiratory issues and improving overall air quality. Additionally, the low dust production minimizes contamination of nearby equipment and surrounding areas, leading to easier cleanup and less post-blasting maintenance. This advantage is particularly valuable when working in sensitive environments, such as food processing facilities, where the presence of dust or contaminants must be strictly controlled.

5. Versatility and Wide Range of Applications

Steel shot is a versatile abrasive media suitable for a wide range of applications. Its hardness, durability, and cleaning efficiency make it ideal for removing tough coatings, rust, and scale from various surfaces, including metals, concrete, and stone. It is commonly used in industries such as shipbuilding, automotive, foundries, and structural steel fabrication. Furthermore, steel shot can be used with different blasting equipment, including wheel blast machines, air blast systems, and wet blasting systems, providing flexibility and compatibility with various setups and project requirements.

Conclusion

Rotocast Steel shot offers numerous advantages that make it a preferred choice in abrasive blasting applications. Its high durability, consistent shape and size, cleaning efficiency, reduced dust generation, and versatility make it a reliable and efficient abrasive media. With its ability to deliver consistent results, reduce downtime, and minimize waste, steel shot proves to be a cost-effective solution for surface preparation and cleaning needs across diverse industries. Whether you are working on large-scale industrial projects or smaller-scale applications.