Steel shot is a highly effective abrasive media for various blasting applications. However, selecting the right type of steel shot is crucial to achieving optimal results and maximizing the efficiency of your blasting process. Here are some factors to consider when choosing the right steel shot for your specific application:

- Hardness: Steel shot is available in different hardness levels, ranging from standard carbon steel shot to more specialized types such as stainless steel shot. The hardness of the steel shot determines its impact energy and its ability to remove coatings, rust, and contaminants. Softer steel shot is suitable for delicate surfaces or where minimal material removal is desired, while harder steel shot is more effective for heavy-duty applications that require aggressive cleaning or surface preparation.

- Size: Steel shot is manufactured in various sizes or granulations, typically indicated by a designated mesh size or shot size number. The size of the steel shot influences the coverage area, intensity of impact, and cleaning efficiency. Finer shot sizes, such as S280 or S330, are suitable for lighter cleaning or achieving a smoother surface finish. On the other hand, larger shot sizes, like S110 or S170, are more effective for removing heavy coatings or rust from robust surfaces.

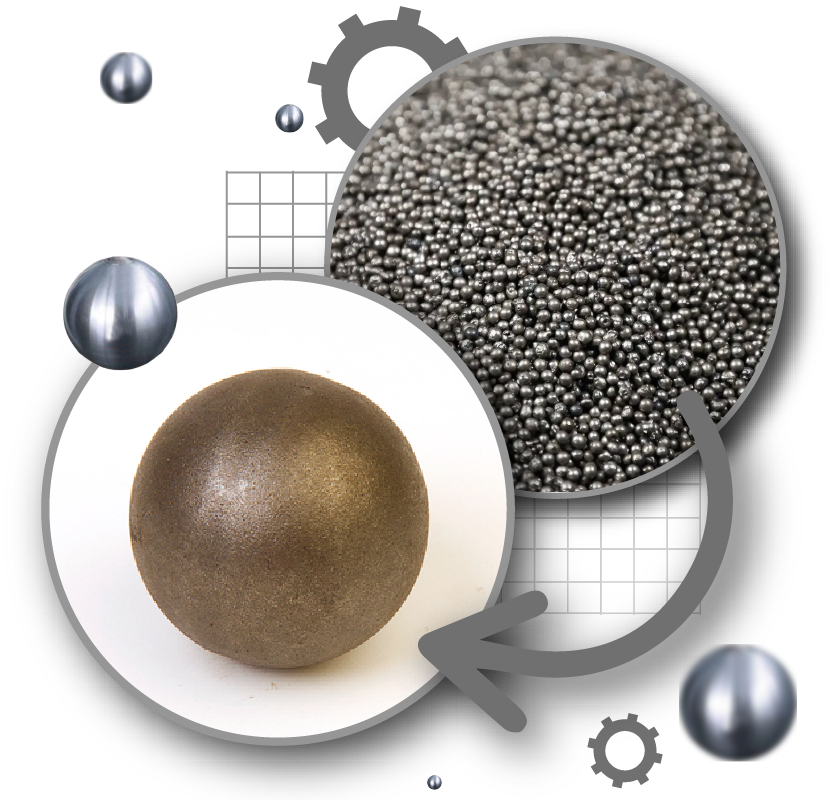

- Shape: Steel shot comes in different shapes, including spherical and angular. Spherical shot provides uniform impact and coverage, making it ideal for achieving consistent results and minimizing substrate damage. Angular shot, on the other hand, delivers more aggressive cutting action and is suitable for applications that require increased material removal or surface profiling. The choice between spherical and angular shot depends on the desired outcome and the sensitivity of the substrate being blasted.

- Recyclability: Consider the recyclability of the steel shot when choosing the right type for your application. Most steel shot can be reused multiple times before it loses its effectiveness. However, some specialized types, such as stainless steel shot, may have limited recyclability due to potential contamination concerns or reduced durability. Evaluate the cost-effectiveness and environmental impact of the steel shot based on its recyclability and the requirements of your specific project.

- Application Requirements: Understand the specific requirements of your blasting application. Consider factors such as the surface material, coating thickness, desired surface finish, and any industry or regulatory standards that need to be met. Different applications, such as shipbuilding, automotive, or architectural restoration, may have specific requirements for surface cleanliness, profile, or roughness. Consult with experts or suppliers who can provide guidance on the appropriate steel shot for your specific application.

- Equipment Compatibility: Ensure that the steel shot you choose is compatible with your blasting equipment. Different blasting systems, such as wheel blast machines, air blast systems, or wet blasting systems, may have specific requirements regarding the size, shape, and hardness of the abrasive media. Consult the equipment manufacturer or supplier to determine the recommended specifications for steel shot to achieve optimal performance and longevity of your blasting equipment.

Conclusion

Choosing the right steel shot for your abrasive blasting application is essential for achieving efficient and effective results. Consider factors such as hardness, size, shape, recyclability, application requirements, and equipment compatibility to select the most suitable steel shot. Proper selection will ensure that you achieve the desired surface cleanliness, profile, and finish while minimizing substrate damage and maximizing the lifespan of your blasting equipment. Consulting with experts or suppliers who specialize in abrasive blasting can provide valuable guidance and assistance in choosing the right steel shot for your specific needs.

Rotocast is one of the most oldest and reliable manufacturer in the field of quality Steel Abrasives Steel Shot, Steel Grit and Alloy Steel Castings. Connect with us for the best range of steel shots and steel grits, Quality & Timely Delivery Guaranteed.