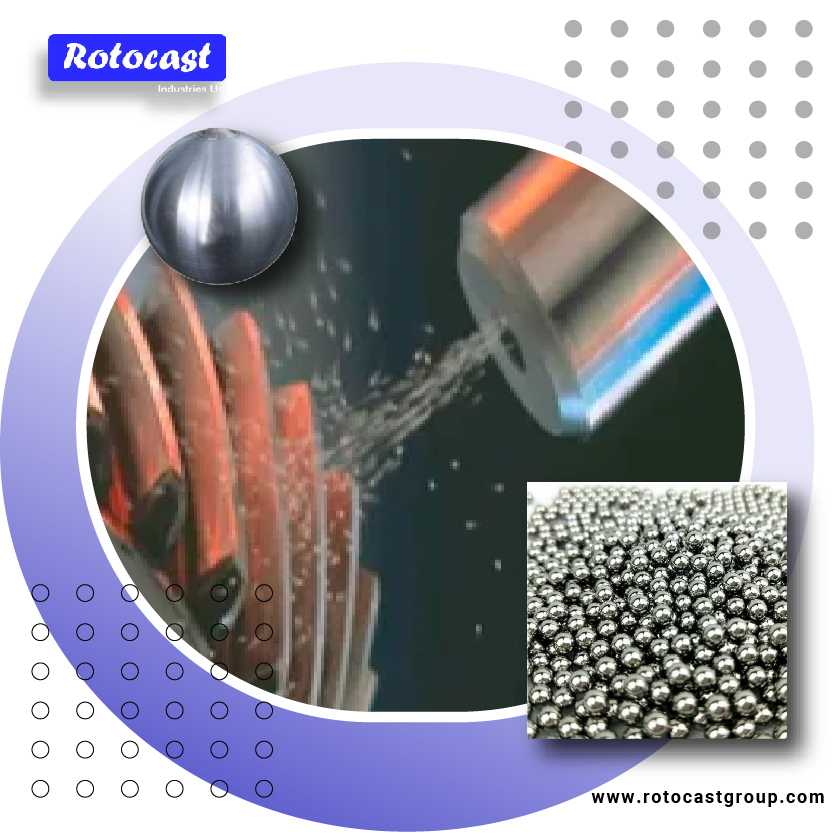

The Benefits of Round Steel Shot for Surface Preparation

When it comes to surface preparation in industrial applications, the choice of abrasive material can significantly impact the quality and efficiency of the process. Round steel shot emerges as a standout choice, offering a range of benefits that contribute to superior results in surface preparation.

- Consistent Impact:

The uniform round shape of steel shots ensures a consistent impact on surfaces during abrasive blasting. This consistency leads to an even and thorough removal of rust, scale, and contaminants, resulting in a smoother and cleaner finish.

- Durability and Reusability:

Round steel shots are known for their durability, making them resilient against wear during the blasting process. Additionally, their sturdy nature allows for multiple uses, providing a cost-effective solution for surface preparation applications.

- Effective Peening:

In applications like shot peening, where metal surfaces undergo controlled impacts to enhance strength and durability, the rounded shape of steel shots ensures efficient and uniform peening, contributing to improved material properties.

- Reduced Surface Distortion:

The rounded profile of steel shots minimizes the risk of surface distortion or damage, especially on delicate or thin-walled materials. This makes them suitable for a broad range of materials and applications.

- Versatility:

Round steel shots are versatile and adaptable to various industries, including automotive, construction, and aerospace. Their ability to be customized in terms of size and hardness adds to their versatility, catering to specific application requirements.

In conclusion, the utilization of round steel shots for surface preparation brings forth a combination of precision, durability, and versatility. Whether it’s achieving a pristine finish or enhancing the strength of metal components, the rounded nature of steel shots proves to be a reliable and effective choice in the realm of surface preparation.