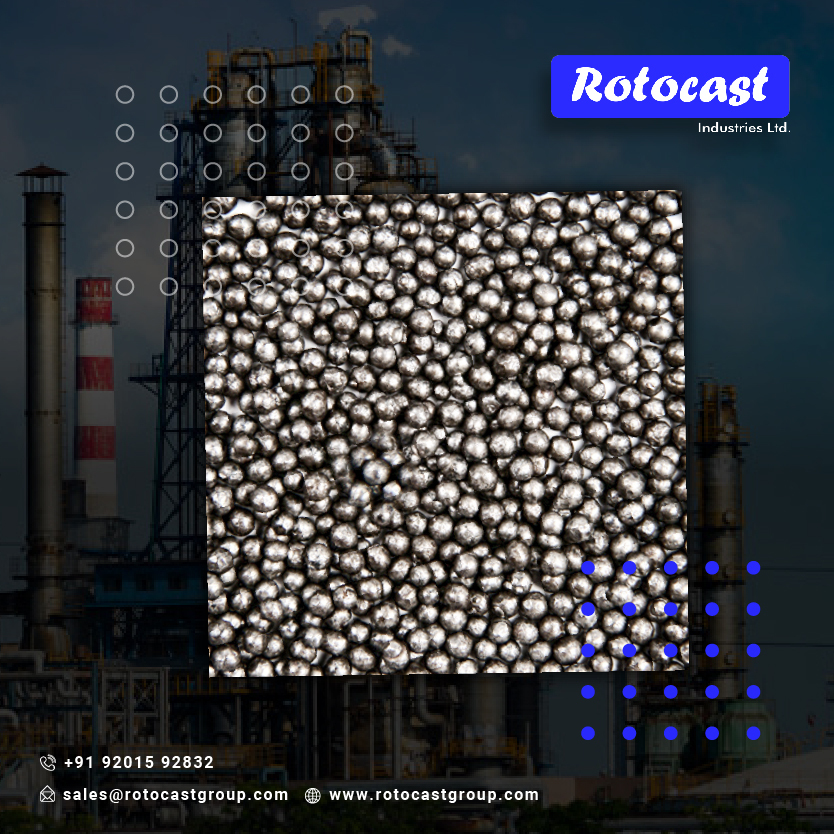

Steel shots, small spherical pellets made from molten steel, are indispensable in various industries owing to their exceptional properties and versatile applications. From manufacturing to construction and beyond, steel shots play a pivotal role in enhancing efficiency and quality across diverse sectors.

1. Automotive Industry: In the automotive sector, steel shots find extensive use in shot peening processes. Shot peening involves bombarding metal surfaces with steel shots to induce compressive stress, thereby improving fatigue life and resistance to corrosion. Components such as gears, crankshafts, and transmission parts undergo shot peening to enhance their durability and performance.

2. Aerospace Industry: Similar to the automotive sector, the aerospace industry relies on shot peening for strengthening critical components like turbine blades, engine parts, and landing gear. Steel shots aid in achieving precise surface modifications, ensuring the structural integrity and longevity of aerospace equipment subjected to extreme conditions.

3. Construction Sector: Steel shots play a crucial role in surface preparation for construction projects. They are used in abrasive blasting techniques to remove rust, scale, and contaminants from metal surfaces before painting or coating. Bridges, pipelines, and structural steelwork benefit from the thorough cleaning and surface profiling facilitated by steel shots, enhancing the adhesion and longevity of protective coatings.

3. Construction Sector: Steel shots play a crucial role in surface preparation for construction projects. They are used in abrasive blasting techniques to remove rust, scale, and contaminants from metal surfaces before painting or coating. Bridges, pipelines, and structural steelwork benefit from the thorough cleaning and surface profiling facilitated by steel shots, enhancing the adhesion and longevity of protective coatings.

4. Shipbuilding and Maritime Industry: In shipbuilding, steel shots are employed for cleaning and descaling steel plates and structures, preparing surfaces for painting and anti-corrosion treatments. Additionally, they are utilized in the maintenance and refurbishment of ships and offshore structures, ensuring compliance with stringent marine safety standards and extending the service life of maritime assets.

5. Manufacturing and Foundry Operations: Steel shots are integral to foundry operations for removing sand residues and imperfections from castings, achieving smooth and defect-free surfaces. Moreover, they serve as effective abrasives in metalworking processes such as deburring, descaling, and surface finishing, contributing to the production of high-precision components across various manufacturing sectors.

6. Energy Sector: In the energy industry, steel shots play a vital role in surface preparation for oil and gas pipelines, wind turbines, and power generation equipment. By facilitating efficient cleaning and coating of critical infrastructure, steel shots help mitigate corrosion and ensure the integrity and reliability of energy installations.

7. Mining and Quarrying: Steel shots find applications in mining and quarrying operations for rock fragmentation and abrasive blasting. They are utilized in shot blasting machines to dislodge overburden, extract minerals, and shape stone surfaces, improving productivity and efficiency in excavation and material processing activities.

8. Metal Fabrication and Welding: In metal fabrication and welding, steel shots are utilized for pre-weld cleaning and surface profiling, enabling optimal weld quality and integrity. They are also employed in shot peening of welded joints to relieve residual stresses and enhance fatigue resistance, particularly in structural steelwork and pressure vessel fabrication.

In conclusion, steel shots are indispensable across a wide range of industries, serving diverse applications from surface preparation and cleaning to strengthening and finishing processes. As technological advancements continue to drive innovation, the demand for steel shots is expected to grow, reinforcing their status as a critical component in modern industrial operations.