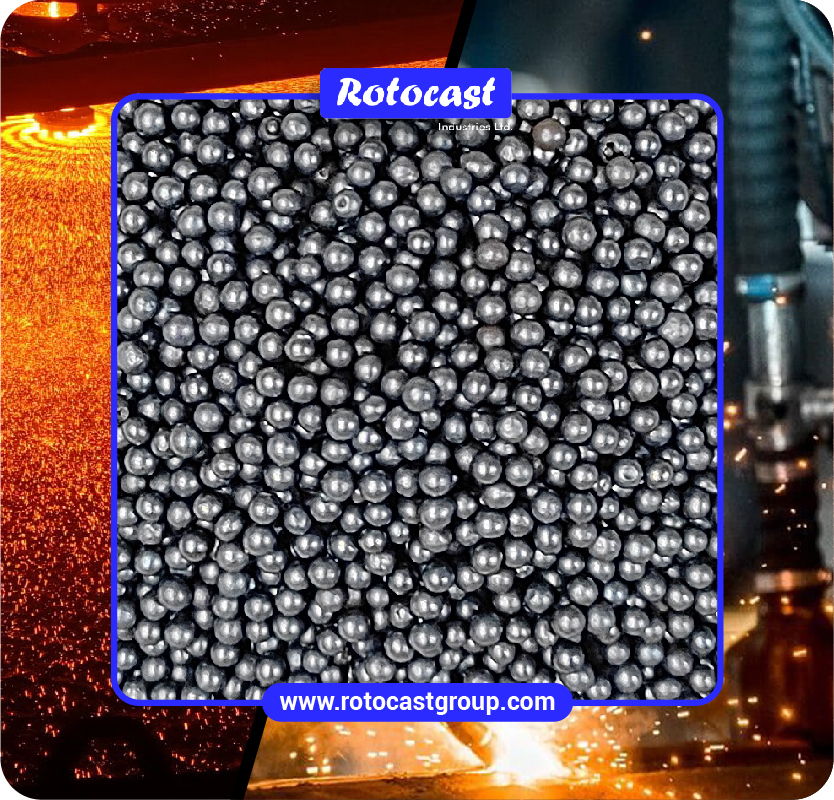

Steel shots, small spherical particles of steel, are revolutionizing India’s metalworking industry by providing superior surface treatment solutions. Used primarily for cleaning, descaling, and surface preparation of metal surfaces, steel shots have become an essential component in various industrial applications, from automotive to construction.

India, with its rapidly growing industrial sector, has witnessed a significant surge in demand for steel shots. This increase is driven by the need for high-quality surface finishing and improved durability of metal products. Steel shots are preferred over other abrasive materials due to their efficiency, cost-effectiveness, and recyclability. They ensure a uniform finish, reducing the need for further treatment and thereby saving time and resources.

One of the primary advantages of using steel shots is their ability to enhance the fatigue life of metal components. By removing surface imperfections and creating compressive stress layers, steel shots significantly improve the structural integrity of metals. This is particularly crucial in the automotive and aerospace industries, where components are subjected to high stress and must adhere to strict quality standards.

One of the primary advantages of using steel shots is their ability to enhance the fatigue life of metal components. By removing surface imperfections and creating compressive stress layers, steel shots significantly improve the structural integrity of metals. This is particularly crucial in the automotive and aerospace industries, where components are subjected to high stress and must adhere to strict quality standards.

The adoption of steel shots in India is also promoting sustainable practices within the metalworking industry. Unlike chemical-based cleaning methods, steel shots do not produce hazardous waste, making them an environmentally friendly option. Their recyclability further contributes to resource conservation, aligning with India’s increasing focus on sustainable industrial practices.

Technological advancements are driving innovation in the production and application of steel shots. Indian manufacturers are investing in state-of-the-art machinery and processes to produce high-quality steel shots that meet international standards. Additionally, research and development efforts are focused on enhancing the properties of steel shots to cater to specific industrial needs, such as improved hardness and durability.

In conclusion, steel shots and steel grits are playing a pivotal role in transforming India’s metalworking industry. Their efficiency, environmental benefits, and ability to improve product quality are driving their widespread adoption. As the industry continues to evolve, steel shots will undoubtedly remain a cornerstone of innovation and progress in metalworking.