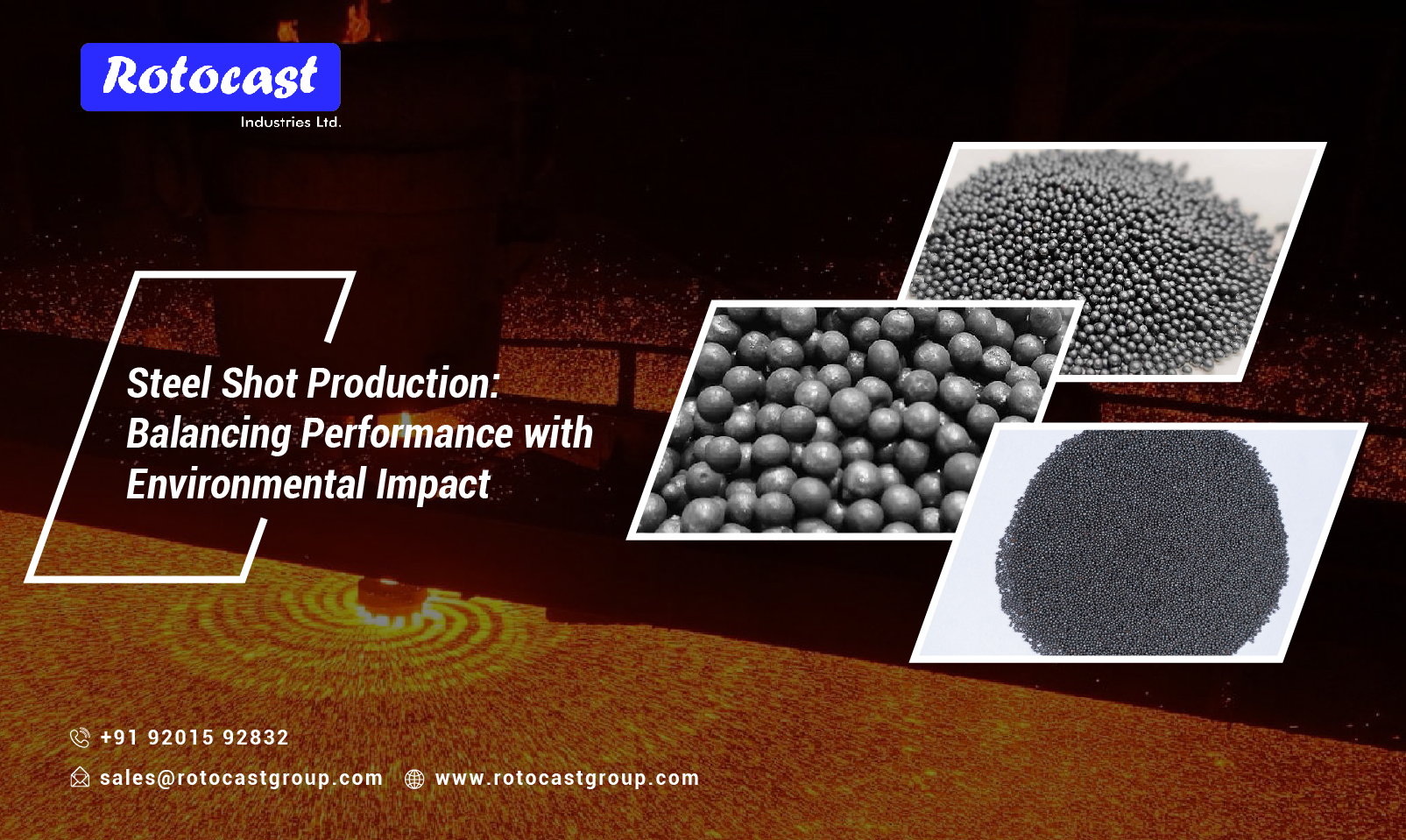

As the demand for high-quality steel shot rises across various industries, balancing performance with environmental sustainability has become a priority for manufacturers like Rotocast. Steel shot, renowned for its durability and efficiency in surface preparation, shot peening, and cleaning applications, plays a critical role in extending the lifespan of industrial equipment. However, as the environmental impacts of manufacturing come under greater scrutiny, aligning steel shot production with sustainable practices is essential to minimize its ecological footprint.

At Rotocast, we have embraced eco-friendly manufacturing processes to achieve this balance. Our advanced technologies not only enhance the quality and performance of our steel shot but also focus on reducing energy consumption and waste during production. By optimizing raw material usage and recycling steel scrap, we ensure that our manufacturing processes are efficient and environmentally responsible. These efforts reflect our commitment to minimizing waste generation and conserving valuable resources throughout the production cycle.

A key aspect of sustainability lies in the lifecycle of the steel shot itself. Rotocast designs its steel shot for maximum recyclability, which means it lasts longer and requires less frequent replacement. This longevity provides significant cost benefits for our customers while simultaneously reducing the environmental impact associated with the disposal and production of new materials. Furthermore, using steel shot in industrial applications often replaces harmful chemicals, contributing to a cleaner and safer work environment. These advantages align with our mission to foster both performance excellence and environmental consciousness.

Continuous improvement is at the core of Rotocast’s operations. By investing in research and development, we remain committed to enhancing energy efficiency, reducing emissions, and exploring sustainable alternatives in the steel shot industry. This dedication ensures that our manufacturing techniques evolve with the latest innovations, enabling us to further minimize the environmental impact of our products. We aim to lead by example, demonstrating that high-performance steel shot can be produced without compromising environmental responsibility.

In conclusion, Rotocast remains dedicated to producing steel shot that meets the stringent demands of our customers while also prioritizing sustainability. Through responsible manufacturing practices, product longevity, and ongoing innovation, we are not only supporting the industrial sector but also contributing to a more sustainable future in the steel shot industry. By prioritizing sustainability, we believe we can achieve both business success and environmental stewardship.