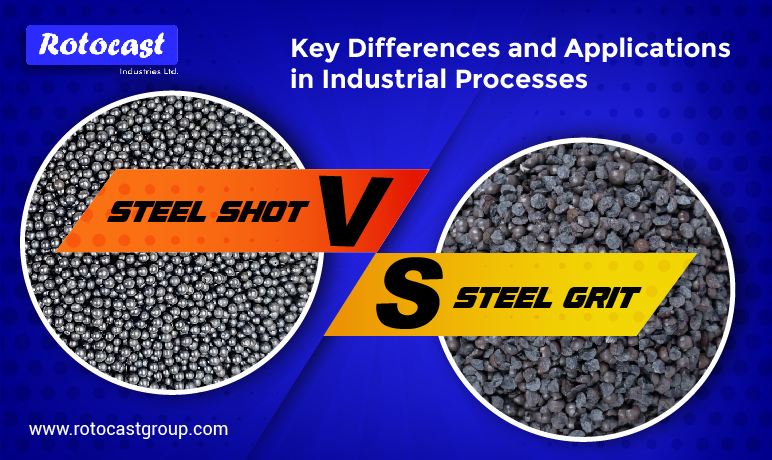

When it comes to abrasive materials used in industrial processes, steel grit and steel shot are two of the most commonly utilized materials. While they may seem similar at first glance, they each offer distinct advantages depending on the application. Understanding these differences is crucial for industries looking to optimize their abrasive blasting, cleaning, and surface preparation processes.

Key Differences between Steel Grit and Steel Shot

Steel Grit is characterized by its angular, sharp edges, which make it highly effective for aggressive surface cleaning and etching. It is commonly used for blasting applications where a rougher, more aggressive impact is required to clean rust, scale, or contaminants from metal surfaces. Steel Grit India is particularly renowned for its durability and efficiency, and steel grit manufacturers in India like Rotocast are known for producing high-quality grits that are used across a wide range of industrial sectors.

On the other hand, steel shot is rounder and smoother, making it ideal for applications that require a more delicate touch, such as polishing or shot peening. Steel shot provides a more uniform finish and is often preferred in applications where the aim is to preserve the integrity of the metal surface while still achieving a high level of cleanliness. This makes steel shot India an essential material for industries like automotive, aerospace, and general manufacturing. Steel shot manufacturers in India have a longstanding reputation for delivering products that meet international standards.

Applications of Steel Grit and Steel Shot

Steel Grits are commonly used in shot blasting operations, particularly in steel casting foundry environments. Their angular shape allows them to effectively clean and prepare steel surfaces, ensuring that they are ready for coating or further processing. Steel grit exporters in India, including Rotocast, provide high-performance grits that are ideal for heavy-duty industrial use, offering both cost-efficiency and long-lasting durability.

Steel Shots, on the other hand, are typically used in surface hardening processes such as shot peening, where the objective is to increase the strength and fatigue resistance of the metal. Steel shot exporters from India play a significant role in global markets by supplying high-quality steel shots for this purpose. Steel shots India are also widely used for cleaning and polishing operations, providing smooth, uniform finishes on components like turbine blades, automotive parts, and castings.

Why Choose Rotocast for Your Steel Grit and Steel Shot Needs?

As a leading steel shot manufacturer in India, Rotocast offers a comprehensive range of steel shots and grits for various industrial applications. Our expertise in steel casting India and commitment to delivering superior products make us a preferred choice for industries worldwide. Whether you need steel grit for abrasive blasting or steel shot for surface polishing, Rotocast ensures you receive products that meet the highest quality standards.

For reliable and efficient solutions, trust Rotocast as your preferred steel grit exporter and steel shot exporter, delivering products that stand the test of time and performance.