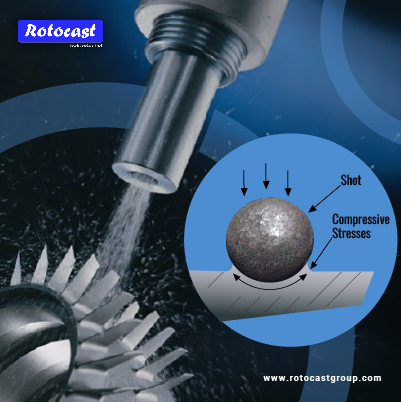

Shot peening is a specialized surface treatment process that enhances the material properties of metals by inducing compressive residual stresses and modifying the surface layer. This mechanical surface treatment involves bombarding the material with small, rounded particles, typically steel shots, at high velocities. The impact of these shots creates localized plastic deformation on the material’s surface, imparting several beneficial effects.

Firstly, shot peening induces compressive stresses in the treated material, counteracting the tensile stresses that often lead to fatigue and stress corrosion cracking. This increased resistance to tensile stress enhances the material’s fatigue life, making it more durable and reliable, particularly in applications subject to cyclic loading.

Secondly, the process refines the microstructure of the material by promoting grain boundary rearrangement and reducing dislocation density. This refinement contributes to improved hardness, wear resistance, and overall mechanical properties of the material.

Secondly, the process refines the microstructure of the material by promoting grain boundary rearrangement and reducing dislocation density. This refinement contributes to improved hardness, wear resistance, and overall mechanical properties of the material.

Additionally, shot peening can work-harden the material, further enhancing its strength and durability. The strengthened surface layer serves as a protective barrier against wear, abrasion, and corrosion.

In summary, shot peening is a powerful technique that imparts compressive stresses, refines microstructure, and work-hardens materials, collectively improving fatigue resistance, hardness, and overall durability, making it a crucial step in enhancing the performance and longevity of various metal components.