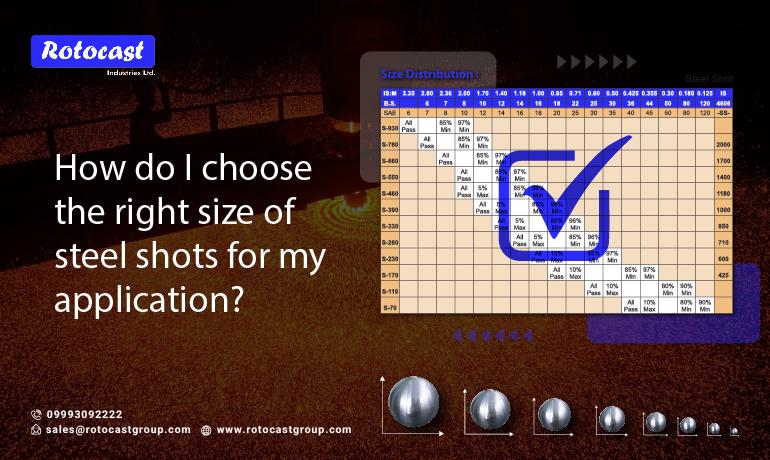

Steel shots and grits are essential components in various industrial applications, including surface preparation, cleaning, and shot peening. However, selecting the appropriate size of steel shots is crucial to achieve optimal results and efficiency in your application. In this guide, we will delve into the factors influencing the choice of steel shot size and provide valuable insights into selecting the right size for your specific needs.

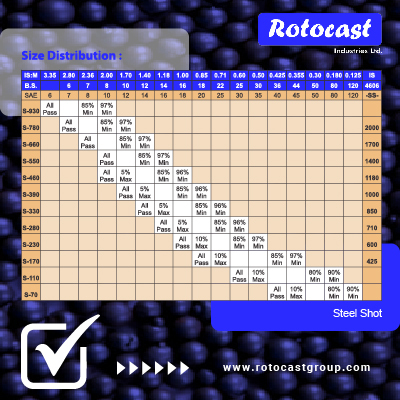

Understanding Steel Shots and Grits: Steel shots and grits are spherical abrasives made from hardened steel, commonly used for surface treatment processes such as cleaning, descaling, and preparing surfaces for coating or painting. They come in various sizes, each designed for specific applications based on factors like surface hardness, roughness requirements, and impact energy.

Factors Influencing Size Selection:

Factors Influencing Size Selection:

- Surface Profile Requirements: The desired surface profile or roughness level of the substrate plays a vital role in determining the size of steel shots to be used. Finer shots produce smoother surfaces suitable for applications requiring high-quality finishes, while larger shots are preferred for applications where a coarser profile is acceptable.

- Substrate Material and Hardness: Consider the material and hardness of the substrate being treated. Softer materials may require smaller shots to avoid surface damage, while harder materials may necessitate larger shots to achieve effective cleaning and profiling.

- Equipment Specifications: The size of steel shots must be compatible with the equipment used for blasting or peening. Ensure that the selected shot size falls within the recommended range specified by the equipment manufacturer to optimize performance and avoid issues such as clogging or excessive wear.

Choosing the Right Size:

- Determine Surface Preparation Requirements: Assess the specific requirements of your application, including the desired surface profile, cleanliness standards, and any coating or paint adhesion specifications.

- Consult with a Steel Shot Manufacturer: Seek guidance from reputable steel shot and grit manufacturers who can provide expert advice based on your application requirements. They can recommend the most suitable size of steel shots and grits tailored to your needs.

- Consider Industry Standards: Familiarize yourself with industry standards and guidelines related to surface preparation and abrasive blasting. Standards such as SSPC (Society for Protective Coatings) and ISO (International Organization for Standardization) provide valuable insights into shot size selection for different applications.

- Conduct Test Trials: Before full-scale implementation, conduct test trials using different sizes of steel shots to evaluate their performance and effectiveness in achieving the desired surface finish and cleanliness level.

Conclusion: Choosing the right size of steel shots is critical for achieving optimal results in surface preparation and treatment applications. By considering factors such as surface profile requirements, substrate material, equipment specifications, and industry standards, you can make informed decisions when selecting the appropriate size of steel shots for your specific application. Consult with reputable steel shot manufacturers and conduct test trials to ensure the chosen size meets your performance expectations and delivers superior results.