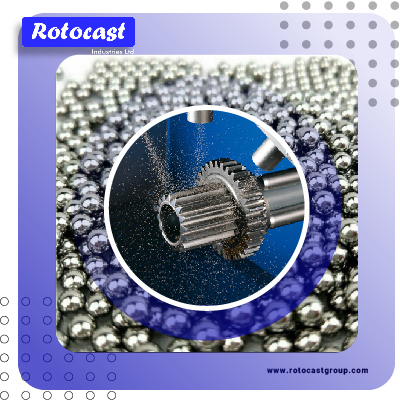

Shot peening is a popular surface enhancement process in a variety of sectors, particularly for increasing the durability and fatigue life of metal components. At the center of this process is the selection of peening media, with steel shots emerging as a popular and successful choice. In this blog, we’ll look at the benefits of using steel shots in shot peening, and how this option can benefit many sectors and applications.

Firstly, steel bullets are extremely durable and consistent in size and shape. This homogeneity enables constant peening results, which leads to predictable and dependable surface improvement effects. Steel shots’ spherical shape provides for efficient coverage of the target surface, resulting in thorough and even treatment, which is critical for obtaining desired material qualities including higher fatigue resistance and surface hardness.

Furthermore, steel bullets have tremendous strength and hardness, allowing them to apply significant compressive pressures to the surface of the metal component being treated. This causes the formation of a favorable residual stress layer, which acts as a barrier against crack initiation and propagation, hence improving the component’s resistance to fatigue failure and increasing its service life.

Furthermore, steel bullets have tremendous strength and hardness, allowing them to apply significant compressive pressures to the surface of the metal component being treated. This causes the formation of a favorable residual stress layer, which acts as a barrier against crack initiation and propagation, hence improving the component’s resistance to fatigue failure and increasing its service life.

Additionally, the recyclability of steel shots is a significant benefit, contributing to both economic effectiveness and environmental sustainability. Steel shots, unlike some other peening media, can be retrieved, cleaned, and reused repeatedly without significantly reducing their peening effectiveness. This not only lowers material costs but also reduces waste output, which aligns with the ideals of sustainable manufacturing methods.

Rotocast recognizes the importance of surface enhancement processes such as shot peening in assuring the performance and endurance of metal components across a wide range of industries. Our knowledge, combined with cutting-edge technology, enables us to offer superior peening solutions that improve the longevity and reliability of our clients’ goods.

In conclusion, the benefits of using steel shots in shot peening are numerous, including durability, effectiveness, and sustainability. By utilizing the unique qualities of steel shots, industries can significantly improve the performance and longevity of their metal components, resulting in increased efficiency and dependability in operations. Rotocast is committed to providing innovative shot peening solutions that meet your changing needs and exceed your expectations.