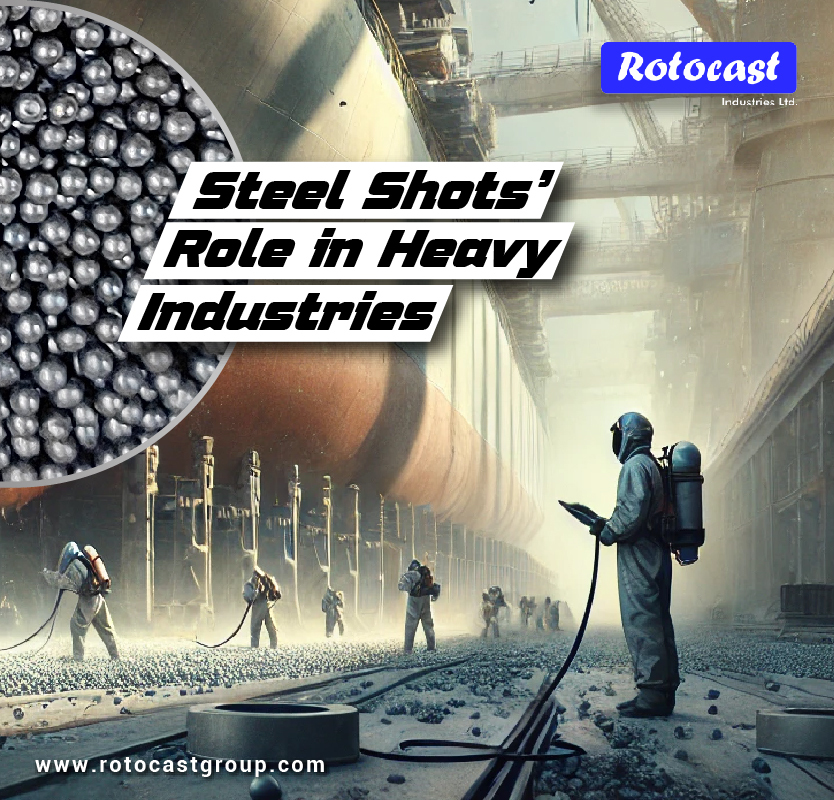

Steel shots play a critical role in shipbuilding and heavy industries, where proper surface preparation is crucial for the durability and performance of metal components. In these industries, tasks such as effective rust removal, surface profiling, and preparation for coatings are essential to ensure that metal surfaces can withstand the harsh conditions they are exposed to. The quality of surface preparation can greatly influence the lifespan and effectiveness of protective coatings, impacting everything from corrosion resistance to overall structural integrity.

Rotocast’s steel shots are engineered to meet the high demands of these heavy-duty applications. Our steel shots deliver superior cleaning performance, making them the preferred choice for removing rust, mill scale, old coatings, and other contaminants. This thorough cleaning process ensures that metal surfaces are properly prepped for the application of new protective layers. By starting with a clean and properly profiled surface, our steel shots help create a strong bond between the metal and the coating, improving adhesion and extending the life of protective treatments.

One of the standout features of Rotocast’s steel shots is their high density and uniform particle size. These attributes significantly enhance impact efficiency, ensuring consistent results even in the most challenging surface preparation tasks. Whether it’s large-scale shipbuilding projects or preparing heavy industrial components, our steel shots provide the reliability and performance needed to handle complex jobs with precision. Their durability also reduces the need for frequent replacements, offering cost efficiency in large projects.

Furthermore, the maritime and heavy industry sectors are increasingly prioritizing sustainability, driven by strict environmental regulations and the need for eco-friendly practices. Rotocast’s steel shots align perfectly with these goals, offering a sustainable alternative to traditional abrasives. Our steel shots are reusable, meaning they can be collected, cleaned, and used multiple times without losing effectiveness. This reusability not only minimizes waste but also reduces the overall environmental impact of the surface preparation process.

Choosing Rotocast as your steel shot supplier means committing to both efficiency and environmental responsibility. Our steel shots not only meet the rigorous standards required for heavy-duty applications but also support sustainability in the maritime and heavy industries. With Rotocast, you get reliable and high-performing products that help ensure your projects are successful and in line with current environmental standards. Our commitment to quality and sustainability makes us a trusted partner for shipbuilders and heavy industries that demand nothing but the best in surface preparation.