In the industrial world, the quality of surface preparation plays a crucial role in determining the effectiveness and longevity of coatings. Steel grit, a key player in this process, significantly enhances coating adhesion and surface finish, leading to superior results in various applications.

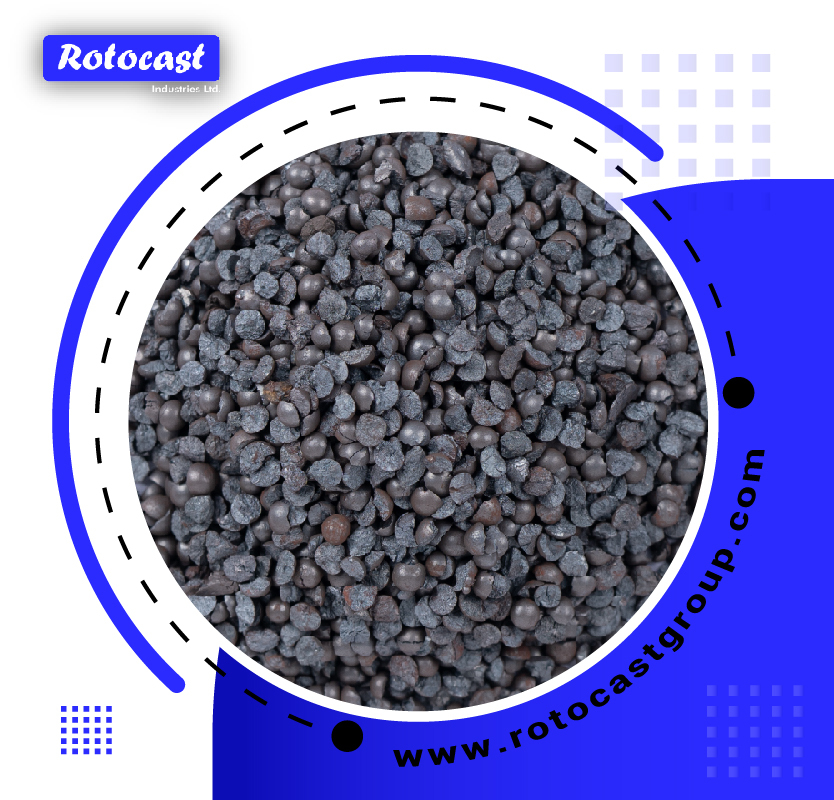

Steel grit, a type of abrasive material, is known for its angular shape and hardness, which makes it ideal for surface preparation tasks. Unlike other abrasives, steel grit provides a rougher profile on the substrate, which is essential for creating a strong bond between the surface and the coating. This rough profile increases the surface area, allowing for better mechanical interlocking and adherence of the coating material. As a result, the coating can perform better under stress, resisting peeling and flaking, and extending the lifespan of the protected surface.

Moreover, steel grit contributes to achieving a more uniform and consistent surface finish. Its sharp edges effectively remove contaminants, rust, and old coatings, ensuring a clean and smooth surface ready for the new coating. This meticulous preparation helps in achieving a higher quality finish, reducing imperfections such as streaks and unevenness that can occur with less effective abrasives.

In addition to enhancing adhesion and finish, steel grit also offers advantages in terms of cost efficiency and environmental impact. Its durability and recyclability mean that it can be used multiple times, reducing the need for frequent replacement and minimizing waste. This makes steel grit a sustainable choice for industries aiming to balance performance with environmental responsibility.

In summary, steel grit is a valuable tool for improving coating adhesion and surface finish. Its ability to create a rough, clean surface ensures that coatings adhere better and last longer, while its durability and recyclability offer added economic and environmental benefits. For industries looking to optimize their coating processes, steel grit provides a reliable and effective solution.